Rubber-tired gantry cranes (RTGs) have become a vital element of modern cargo handling facilities, such as container terminals and intermodal yards. These versatile machines offer the flexibility to lift and transport heavy cargo containers across the storage yard efficiently. Learning how to operate an RTG is crucial not only for the crane operators but also for the overall productivity and safety of the terminal. In this comprehensive guide, we will delve into the intricate operations of an RTG, emphasizing the key steps, safety protocols, and best practices that ensure the smooth and efficient handling of cargo.

Understanding the Rubber-Tired Gantry Crane

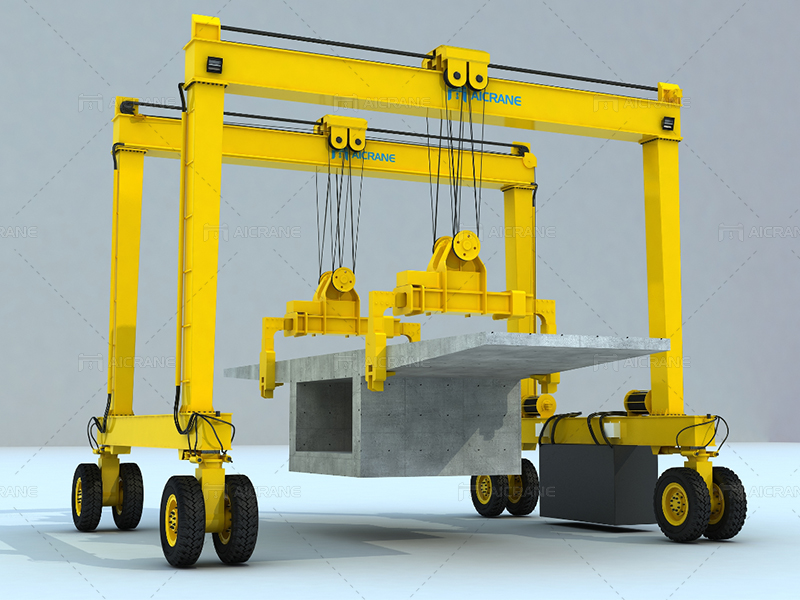

Before we dive into the details of how to operate an RTG, it’s essential to understand the crane’s structure and functionality. A rubber tired gantry crane is a mobile gantry crane equipped with rubber tires, which allows it to move horizontally along a predefined path within the container yard. The crane’s primary functions include lifting, moving, and stacking cargo containers.

Key Components of an RTG:

Frame: The frame of an RTG serves as the main structure, supporting the other components.

Cabin: The operator’s cabin is where the crane operator controls and monitors the crane’s operations.

Spreader: The spreader is attached to the crane’s trolley and is used to grasp and lift containers.

Wheels: RTGs typically have eight or more rubber wheels that enable them to move along the yard’s designated paths.

Electrical System: The crane relies on an intricate electrical system to control various functions, including movement, lifting, and safety features.

Operating an RTG: Step-by-Step Guide

Operating an RTG crane involves a series of steps that require precision, attentiveness, and adherence to safety protocols. Here is a comprehensive guide on how to operate an RTG effectively:

Pre-Operational Checks:

Before initiating any crane operation, it is crucial to conduct thorough pre-operational checks. This step helps ensure that the crane is in optimal working condition and minimizes the risk of accidents.

- Verify that all safety devices, such as limit switches, emergency stops, and alarms, are functional.

- Inspect the tires for signs of wear, damage, or low pressure. Proper tire maintenance is critical for smooth operation.

- Examine the spreader and its associated components to ensure they are in working order.

- Check the crane’s electrical system, including the control panel and cabin equipment, for any malfunctions or warning indicators.

Entering the Operator’s Cabin:

Once the pre-operational checks are completed, the operator should enter the cabin and prepare for crane operation.

- Ensure that all cabin controls are within easy reach and functioning correctly.

- Confirm that the communication systems, such as radios and intercoms, are operational for coordination with ground personnel.

- Adjust the seat and controls to the operator’s preference for comfort and visibility.

Crane Start-Up:

Starting the RTG requires a systematic approach to ensure safe and efficient operation.

- Power up the crane by following the designated startup procedures as outlined in the operator’s manual.

- Verify that all warning lights and alarms on the control panel are functioning and visible.

- Check the cabin’s air conditioning and ventilation systems for comfort during extended shifts.

Positioning the RTG:

Before lifting containers, the operator must position the rubber tyre gantry crane correctly.

- Use the cabin’s joystick or control panel to move the crane to the desired location.

- Ensure that the crane is on level ground to prevent stability issues during lifting.

- Confirm that the spreader is correctly positioned for container pickup.

Container Lifting:

Lifting a container involves a series of steps that must be executed with precision.

- Approach the container slowly and align the spreader with the container’s corners.

- Gradually lower the spreader onto the container and engage the twist locks to secure it in place.

- Lift the container slowly, ensuring that it is stable and balanced.

- Be attentive to the load’s weight capacity and ensure it does not exceed the crane’s specified limits.

Container Transport:

Once the container is securely lifted, the operator must transport it to the desired location within the yard.

- Drive the RTG carefully, adhering to designated paths and obeying speed limits to prevent accidents and damage to containers.

- Communicate with ground personnel to coordinate the precise positioning of the container.

- Gradually lower the container in its designated location, ensuring it is properly stacked.

Post-Operational Checks:

After completing the lifting and transport of containers, it is essential to conduct post-operational checks.

- Ensure that all twist locks are disengaged and the spreader is free from the container.

- Verify that all warning lights and alarms are reset.

- Conduct a final visual inspection of the crane’s condition, tires, and electrical systems.

Safety and Best Practices

The safe operation of an RTG crane is paramount. Here are some safety protocols and best practices that should be followed at all times:

Operator Training: Operators should undergo comprehensive training on RTG operation, safety procedures, and emergency protocols.

Load Capacity Awareness: Operators must be aware of the crane’s load capacity and never exceed it to prevent accidents and structural damage.

Adherence to Traffic Rules: While operating the crane, follow designated traffic rules, speed limits, and signage within the terminal.

Communication: Maintain clear and effective communication with ground personnel and other crane operators to prevent accidents and ensure efficient cargo handling.

Emergency Procedures: Operators should be well-versed in emergency procedures, including equipment shutdown, fire response, and first aid.

Preventive Maintenance: Regular maintenance and inspections of the gantry crane equipment, including tire pressure checks, are crucial for safe and efficient operations.

Conclusion

Operating a rubber-tired gantry crane requires careful attention to detail, adherence to safety protocols, and precision in cargo handling. By following the step-by-step guide outlined in this article, operators can ensure the smooth and efficient movement of cargo containers within container terminals and intermodal yards. Safety should always be the top priority, and a well-trained and vigilant operator is essential to the success of these essential machines in the world of logistics and cargo handling.